SPS, as a world leader in contactless and dual interface card manufacturing technologies, is constantly adapting to the evolution of cardholders’ demand by introducing GoGreen S-Lam™, its new easy-to-integrate eco-friendly PETG, rPETG and rPVC card material range for banking card manufacturers.

ROUSSET, FRANCE, November 26, 2021 – Citizens worldwide are becoming more eco-conscious and are willing to align their purchase decisions with their values. This goes through a change of habits on many levels, including having a fresh look at the cards they want to see in their wallet. Everyone is getting increasingly concerned with one’s ecological footprint, the pollution triggered by plastic waste and, more globally, by environmental issues. It is anticipated that by 2025, around 25% of dual interface card bodies will be manufactured with eco-friendly materials.

Supporting citizens in matching their behavior with their values, SPS is introducing GoGreen S-Lam™, its series of new card materials, which reduce the dissemination of toxic components into the environment. Included into its global portfolio, SPS proposes a full set of components and options to support its customers in manufacturing the most suitable, qualified and certified, sustainable solutions. Made from recycled sources, these materials will be able to degrade without dispersing chlore-based harmful chemicals while, at the same time, allowing an easy integration with existing manufacturing tools and methods already in use by card vendors.

Thanks to these new recycled and chloride-free plastic materials proposed by SPS, card manufacturers will be able to expand their offer and adapt to the demand of issuers willing to propose multiple options to their cardholders. This way, card issuers can propose eco-friendly cards in addition to their existing offer that already includes standard cards and high-end cards such as metal cards and customized modules and S-Lam™. This extensive offer opens options for the marketing teams of financial institutions as it is now evident that consumers are not only demanding ecological efforts from corporations but are also ready to accept higher prices for environmentally-friendly products and services.

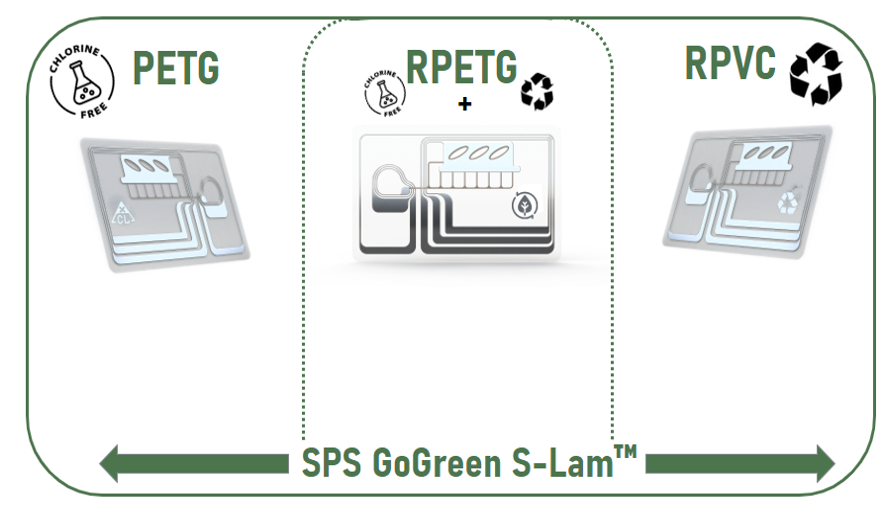

SPS new GoGreen S-Lam™ portfolio of eco-friendly materials includes the following from strategic suppliers:

· Recycled PVC GoGreen rPVC (Recycled PVC), which contains a minimum of 99% of recycled industrial plastic, leading to a carbon footprint reduction of about 48%. With GoGreen rPVC, the card manufacturing process remains similar to classical PVC

· Chloride free PETG (Glycol Polyethylene Terephthalate) and rPETG (Recycled PETG), which contain no chlore-based harmful chemicals, leading to a faster degradability and almost infinite recyclability. These materials bring a carbon footprint reduction of 10% for PETG and of 67% for rPETG. With GoGreen PETG and rPETG, the card manufacturing process remains unchanged compared to traditional cards.

Thanks to these new materials, card manufacturers that use the SPS inductive coupling manufacturing process are in the best position to answer to their customer requirements and propose them cards that will keep the same qualities of reliability, durability and cost-effectiveness as the ones made in legacy materials while being a lot more eco-friendly.

Jean-Baptiste Leos, marketing director for banking products at SPS declares: “We are happy to be always more in line with society concerns and demands and, at the same time, to keep on delivering the best-in-class products to card manufacturers. With our new GoGreen S-Lam™ range, we make sure card vendors can answer all market requirements while keeping the industrial advantages of SPS inductive coupling process.”

SPS new recycled and chloride-free materials allow the same series of SPS specific security features as other card materials. With these new materials, it is easy to manufacture metallic or non-metallic foil artworks, non-standard card formats, M2D™ (Mark on Module Design) and CAI™ (Customized Antenna Image) cards.

SPS new rPVC, PETG and rPETG products, part of the GoGreen S-Lam™ range, are already available for volume orders from SPS.

About SPS

With the SPS brand, IN Groupe opens its secure components technology to all card and document manufacturers. SPS is specialized in the design, manufacturing and sale of contactless solutions dedicated to ID cards, e-passport and dual interface banking cards. Headquartered in Rousset, France, with a subsidiary in Singapore, SPS employs 250 people. The company specializes in contactless and dual-interface products, with a recognized micro packaging expertise. SPS has filed over 120 patents supporting its exclusive technologies. More information at http://www.s-p-s.com

Contact

Jean Baptiste Leos, Marketing Director for banking products, SPS, contactsps@s-p-s.com

Phone: +33 4 42 53 84 83

SPS is part of the IN Groupe.

A partner of the French government for close to 500 years, IN Groupe offers identity solutions and secure digital services, at the leading edge of technology and integrating electronics and biometrics.

From components to services and from documents to interoperable systems, IN Groupe is a global specialist in identity and secure digital services. The institution plays a daily role in facilitating everyone's life: helping states exercise their sovereignty, citizens protect their identity and businesses preserve their integrity.

Whatever the issue, IN Groupe, a company for digital sovereignty, contributes to asserting a fundamental right for everyone: the right to be you.

Based in Paris, the IN Groupe has two production centers and employs more than 1000 employees, of which over a third is dedicated to technology development.

Contact: IN Groupe

Romain Galesne-Fontaine | +33 1 40 58 30 00 | media@ingroupe.com